Selecting the perfect gasket cutting machine is a crucial decision for manufacturers, engineers, and maintenance professionals who deal with sealing applications. A high-quality gasket cutting machine not only improves production efficiency but also ensures precision, reduces material waste, and guarantees consistent product quality. However, with the wide range of models and technologies available in the market today, making the right choice can seem overwhelming. This comprehensive guide will walk you through everything you need to know before purchasing a gasket cutting machine, from understanding different types to evaluating technical specifications and essential buying factors.

Understanding What a Gasket Cutting Machine Is

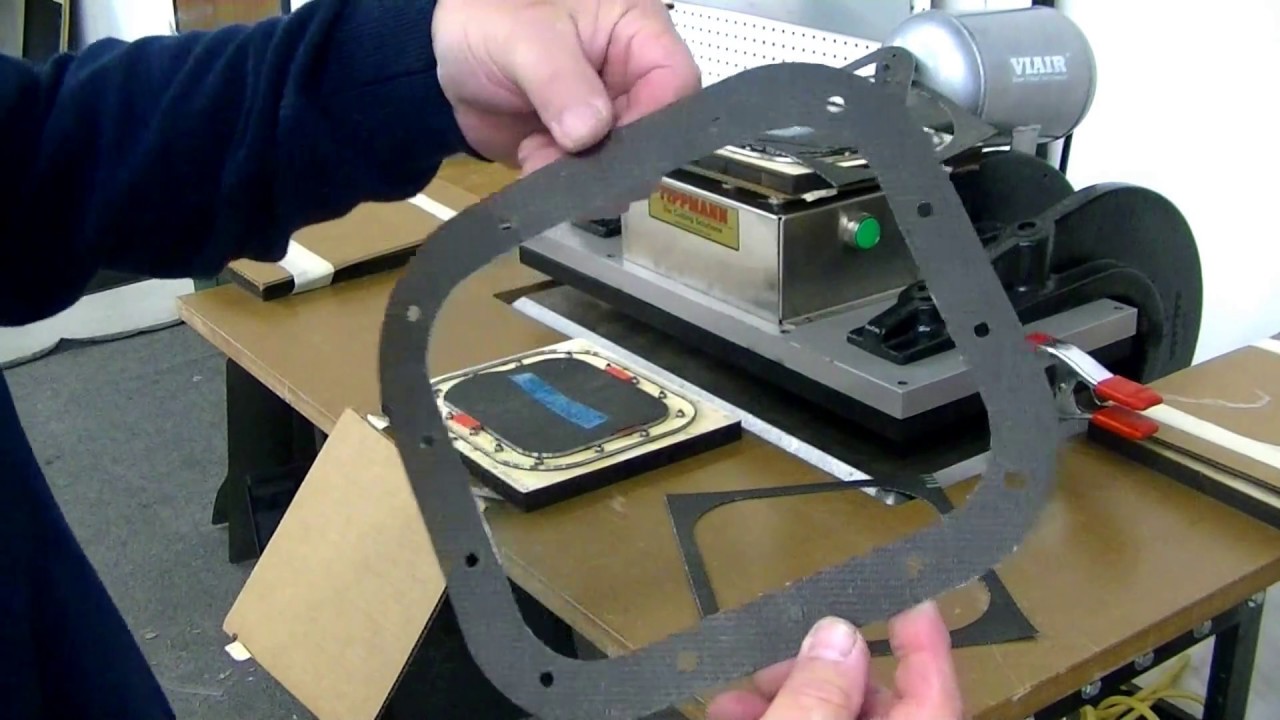

A gasket cutting machine is a specialized piece of equipment designed to cut gaskets—mechanical seals that fill the space between two or more surfaces to prevent leakage of gases or liquids. Gaskets are used in a wide range of industries, including automotive, aerospace, oil and gas, plumbing, and manufacturing. Traditionally, gaskets were cut manually using hand tools or die-cutting methods, but modern gasket cutting machines use advanced technology to deliver faster, more accurate, and cost-efficient results.

Modern gasket cutting machines can handle various materials such as rubber, cork, graphite, PTFE, silicone, fiber, and non-asbestos materials. They are equipped with computer numerical control (CNC) systems or automated cutting heads that ensure precision and repeatability. Depending on your production requirements, you can choose between manual, semi-automatic, or fully automatic machines.

Types of Gasket Cutting Machines

Manual Gasket Cutters

Manual gasket cutters are ideal for small-scale or maintenance operations. These machines are operated by hand and are suitable for cutting soft materials or simple shapes. They are affordable, easy to use, and require minimal maintenance. However, they may not be suitable for high-volume or complex cutting tasks that demand high precision.

Die Cutting Machines

Die cutting machines use pre-made dies to cut gaskets into specific shapes. They are excellent for mass production where the same design is needed repeatedly. Although die cutting ensures uniformity and speed, it lacks flexibility, as new dies must be made for each design change, which can be expensive and time-consuming.

CNC Gasket Cutting Machines

CNC gasket cutting machines represent the most advanced and versatile technology in the industry. Controlled by computer software, these machines use digital designs to cut gaskets with extreme precision. They can cut complex shapes, handle multiple materials, and switch between designs quickly without requiring new tooling. CNC machines are ideal for high-volume production and custom gasket manufacturing.

Water Jet Cutting Machines

Water jet cutting machines use a high-pressure stream of water, sometimes mixed with abrasive materials, to cut gaskets with remarkable accuracy. This method is perfect for cutting thick or hard materials such as metal-reinforced rubber, graphite, or composite gaskets. The process produces no heat, reducing the risk of material deformation.

Laser Cutting Machines

Laser cutting machines use focused laser beams to cut gaskets with pinpoint precision. They are suitable for thin materials and applications requiring intricate designs. Laser cutting is clean, fast, and efficient but may not be suitable for all materials, especially those sensitive to heat.

Key Factors to Consider When Choosing a Gasket Cutting Machine

1. Material Compatibility

The first factor to consider is the type of materials you’ll be working with. Some machines are optimized for soft materials like rubber and foam, while others are designed to handle harder or multi-layered materials. Always ensure the machine you choose is capable of cutting the full range of gasket materials you use in your operations.

2. Production Volume

If you produce gaskets on a small scale or for maintenance purposes, a manual or semi-automatic machine may suffice. For high-volume or industrial-scale production, a CNC gasket cutting machine or water jet cutter will deliver the efficiency, speed, and precision you need.

3. Cutting Accuracy and Precision

The accuracy of your gasket cutting machine determines the quality and consistency of your gaskets. CNC and laser cutting machines are known for their exceptional precision, capable of maintaining tight tolerances even during long production runs.

4. Machine Speed and Efficiency

Production speed is vital in manufacturing environments. Automated machines like CNC and laser cutters can significantly reduce production time while maintaining accuracy. Consider the machine’s cutting speed, tool change time, and automation features when evaluating efficiency.

5. Software and Automation Features

Modern gasket cutting machines often come with integrated design software or compatibility with CAD/CAM programs. These features allow you to upload digital gasket designs directly to the machine, saving time and reducing human error. Look for user-friendly software that supports your preferred file formats.

6. Machine Size and Workspace Requirements

The size of the machine should match your available workspace and the dimensions of the materials you typically handle. Large-format gasket cutting machines are ideal for big sheets or high-volume production, while compact models are better suited for smaller workshops.

7. Maintenance and Support

Before purchasing, consider the machine’s maintenance needs and the availability of technical support from the manufacturer. A reliable supplier should provide training, spare parts, and after-sales service to minimize downtime.

8. Cost and Return on Investment (ROI)

While price is a major factor, it’s important to evaluate the overall value rather than just the initial cost. A more expensive CNC gasket cutting machine may provide a faster return on investment through reduced waste, higher productivity, and greater precision.

Advantages of Using a Gasket Cutting Machine

- Precision and Consistency: Modern machines deliver exact cuts, ensuring every gasket meets required specifications.

- Time Efficiency: Automated systems dramatically reduce cutting time compared to manual methods.

- Material Optimization: Advanced nesting software minimizes material waste, improving cost efficiency.

- Versatility: One machine can handle multiple materials and designs.

- Reduced Labor Costs: Automation minimizes the need for manual labor, reducing operational costs.

Common Applications of Gasket Cutting Machines

Gasket cutting machines are used across a wide range of industries. In the automotive industry, they produce seals for engines, transmissions, and exhaust systems. In aerospace, precision-cut gaskets ensure safe operation in extreme conditions. Oil and gas sectors use gasket cutters to produce high-pressure seals for pipelines and valves, while manufacturing and HVAC companies rely on them for equipment and duct sealing.

Tips for Getting the Best Performance from Your Gasket Cutting Machine

- Keep cutting blades and heads sharp and clean for optimal performance.

- Regularly inspect the machine for wear and calibration errors.

- Train operators thoroughly on both hardware and software use.

- Use high-quality gasket materials to ensure consistent results.

- Schedule routine maintenance and follow manufacturer guidelines strictly.

Future Trends in Gasket Cutting Technology

The gasket cutting industry continues to evolve with advancements in automation, software integration, and sustainability. Modern machines are increasingly equipped with AI-assisted cutting algorithms for better accuracy and IoT connectivity for real-time monitoring. Eco-friendly production methods, such as energy-efficient motors and recyclable materials, are also becoming standard.

Conclusion

Choosing the right gasket cutting machine is an investment that can significantly impact your production quality, efficiency, and profitability. By carefully evaluating your material requirements, production volume, precision needs, and budget, you can identify the machine that best suits your business. Whether you opt for a manual cutter, CNC system, or water jet machine, prioritizing quality, reliability, and support will ensure long-term success. A well-chosen gasket cutting machine is more than just equipment—it’s a vital tool for achieving excellence in gasket manufacturing and sealing solutions.