China Final Inspection: What You Need to Know

China has emerged as a global manufacturing hub, supplying a wide array of products to markets worldwide. As a result, quality assurance and final inspection have become vital stages in the production process. Manufacturers, importers, and exporters alike must understand the significance of China final inspection and its role in ensuring the delivery of high-quality products to customers. In this article, we will explore what China final inspection entails, its purpose, benefits, key considerations, and best practices.

What is China Final Inspection?

China final inspection, also known as pre-shipment inspection or third-party inspection, is a crucial step in the production process for products manufactured in China. It involves conducting a comprehensive inspection of the goods before they are shipped to the importer or customer. The inspection is carried out by independent quality control agencies or inspectors who are not affiliated with the manufacturer. This impartiality ensures a fair and accurate assessment of the product’s quality and conformity to agreed-upon specifications and standards.

Purpose of China Final Inspection

The primary purpose of China final inspection is to identify and address any defects, discrepancies, or deviations in the product’s quality, packaging, labeling, and overall condition before it leaves the factory. The inspection helps to ensure that the goods meet the buyer’s requirements and expectations, thereby reducing the risk of costly product recalls, returns, or customer complaints. By catching potential issues early on, the inspection process enhances product reliability and customer satisfaction.

Benefits of China Final Inspection

- Quality Assurance: Final inspection in China ensures that the products meet the agreed-upon quality standards and specifications, maintaining consistent quality across production batches.

- Risk Mitigation: By identifying and resolving defects before shipping, importers can avoid potential financial losses and reputational damage associated with substandard or non-compliant products.

- Compliance with Regulations: China final inspection helps ensure that the products comply with relevant international and local regulations, preventing legal issues and barriers to market entry in destination countries.

- Supplier Accountability: Inspections promote accountability among manufacturers, as they are aware that their products will be thoroughly assessed before shipment.

- Better Supplier Selection: Importers can use inspection results to evaluate and choose reliable suppliers capable of consistently delivering high-quality products.

Key Considerations for China Final Inspection

- Inspection Agency Selection: Choose a reputable and experienced inspection agency that specializes in your product category and is well-versed in Chinese manufacturing practices.

- Inspection Criteria: Clearly define inspection criteria, including quality standards, specifications, and other relevant requirements, in collaboration with the manufacturer.

- Sampling Plan: Determine a statistically sound sampling plan to ensure that inspection results are representative of the entire production batch.

- On-Site or Remote Inspection: Decide whether an on-site inspection or a remote inspection using advanced technologies, such as video streaming, is more appropriate for your specific needs.

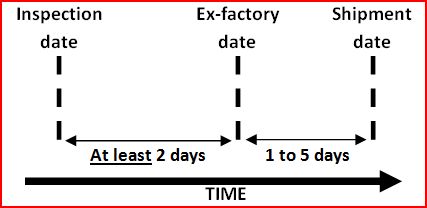

- Timing: Schedule the final inspection at the right time in the production process, typically when at least 80% of the goods are completed and packed.

Best Practices for China Final Inspection

- Communicate Expectations: Establish open communication channels with the manufacturer to clarify expectations and requirements before the inspection.

- Randomize Inspection Dates: Avoid informing the supplier in advance about the inspection date to get an accurate assessment of routine production quality.

- Verify Necessary Documentation: Ensure that all necessary documents, such as production records, test reports, and compliance certificates, are readily available during the inspection.

- Independent Inspection: Whenever possible, engage a third-party inspection agency independent of the buyer and the manufacturer to ensure impartiality.

Conclusion

China final inspection plays a pivotal role in guaranteeing the quality and compliance of products manufactured in China. It is a critical step for importers and exporters to minimize risks, uphold quality standards, and meet customer expectations. By adhering to best practices and partnering with reliable inspection agencies, businesses can confidently navigate the global supply chain and deliver superior products to the market. Ultimately, a thorough and successful final inspection contributes to the growth and reputation of businesses in an increasingly competitive global marketplace.